StarWorks

Ronchii Ronchi eyepiece 150LPI

Ronchii Ronchi eyepiece 150LPI

Couldn't load pickup availability

Ronchi-ruling is an optical element used to evaluate the surface accuracy of lenses and other components.

Ronchi-ruling is a pattern of regularly arranged parallel lines. The width of the parallel lines is equal to the width of the space.

This optical element is used to evaluate the surface accuracy of lenses, etc.

----------------

Usage

----------------

The method of setting up a telescope and judging with bright fixed stars has a large influence of seeing, and in the dark, it is not a good way to judge well, only taking a lot of time and effort.

The method of using a star tester (an artificial bright star), which is separately exhibited, is not affected by seeing and can be used to make accurate judgments.

When using a star tester (artificial bright star), a 300μ hole is optimal.

(1) Attach it to the telescope instead of the eyepiece. The stripe should be vertical.

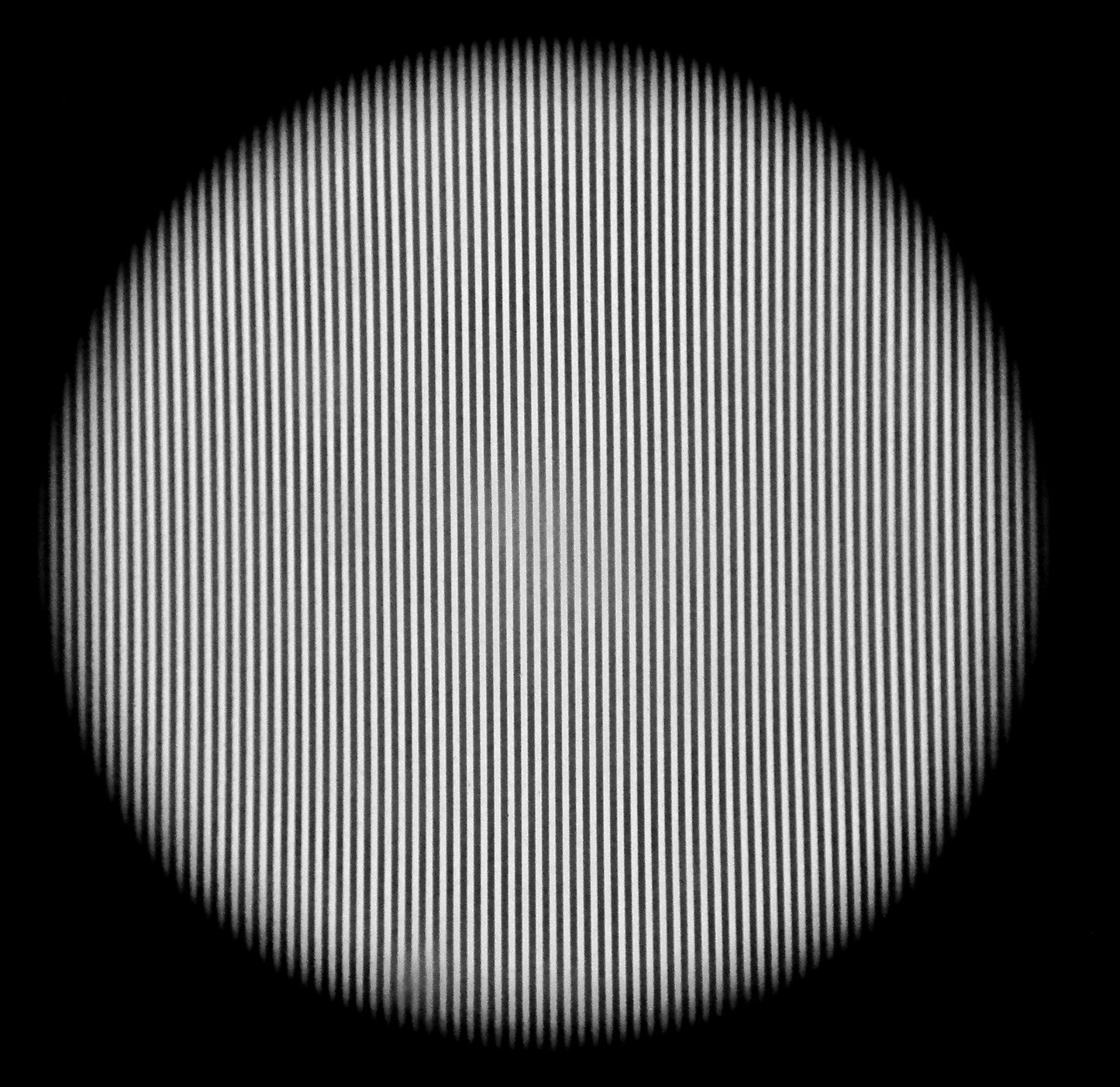

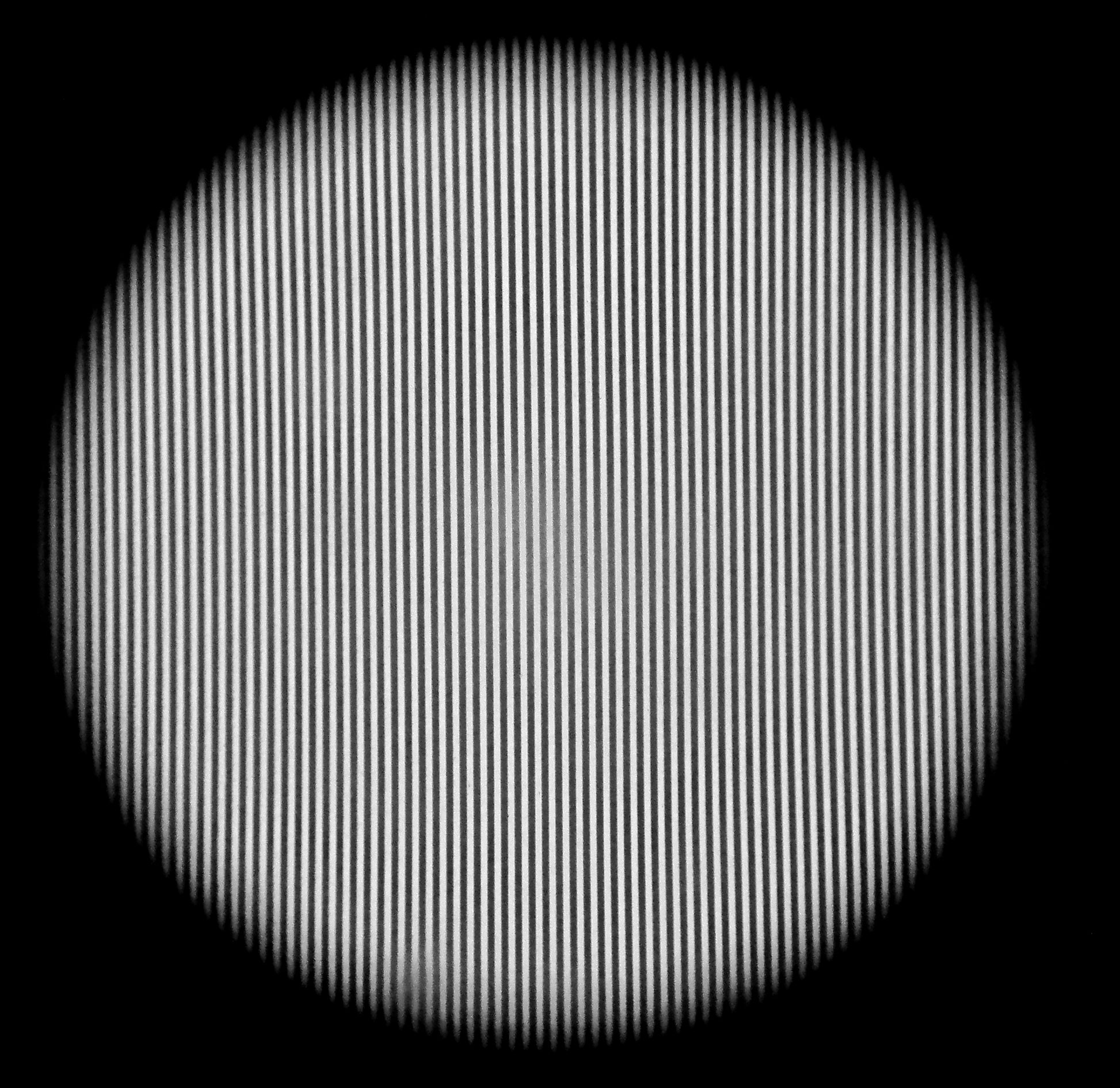

(2) The position where the stripes are enlarged and only one stripe is enlarged is the direct focus (neutral) position.

(3) From the direct focus position, move the focus forward until seven lines (one in the center and three on the left and right) are visible.

Five lines (one in the center and two on the left and right) are also acceptable. Choose the one that is easier to see.

From the direct focus position, move the focus backward until seven lines (one in the center and three on the left and right sides) are visible.

Five lines (one in the center and two on the left and right sides) are also acceptable. Choose the one that is easier to see.

Compare the conditions of (3) and (4).

If the stripes are equally spaced and vertical at both the front and rear pin positions, the optical system has good accuracy.

If the left and right sides look different, if the line spacing is open or bent, or if the opening is different at the top and bottom, the optical system is defective.

----------------

Visibility

----------------

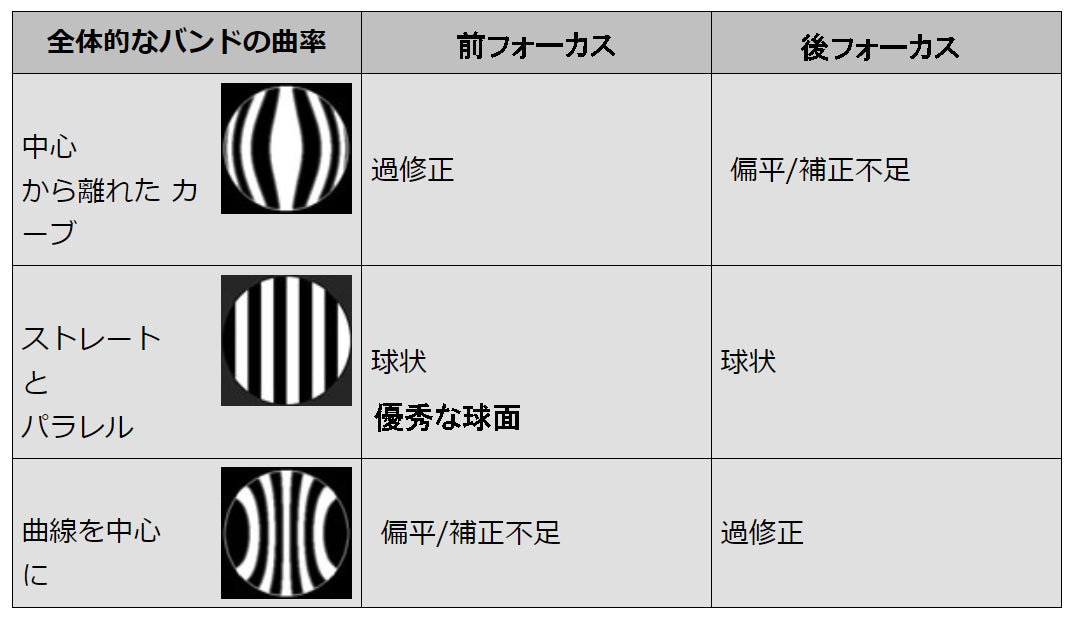

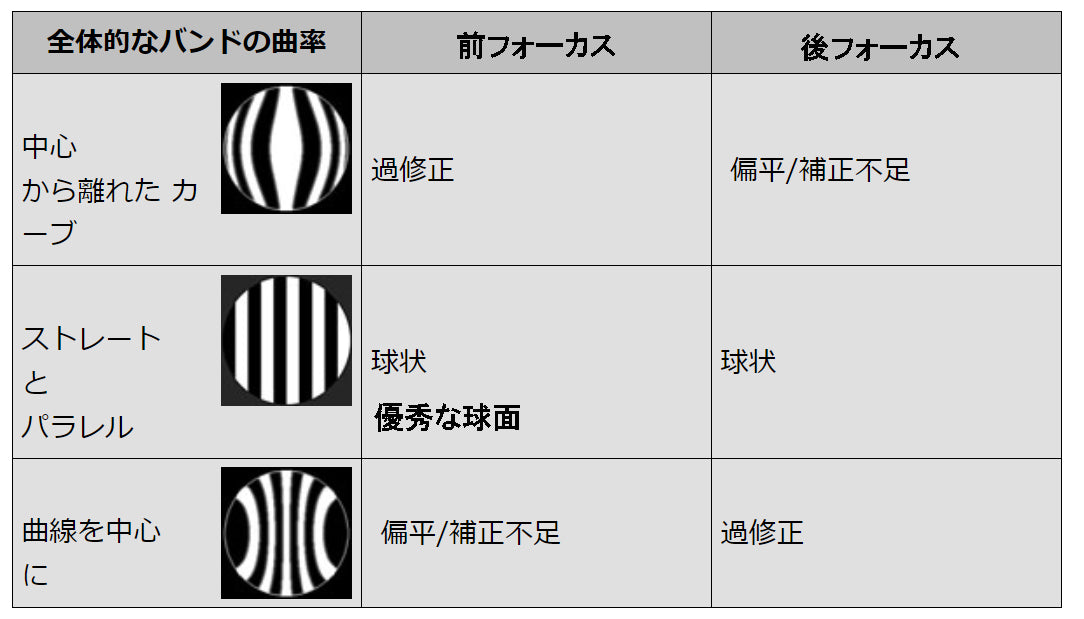

1. In-focus image (stripes are evenly spaced and clean vertical) Out-of-focus image warehouse (stripes are evenly spaced and clean vertical) Excellent optics

2. In-focus image (stripes are tilted) Out-of-focus image warehouse (stripes are tilted opposite of the previous image) As Aberration is present (serious shortcoming)

3. In-focus image (shrunken circle in the center) Out-of-focus image warehouse (enlarged circle in the center) Mountain in the center (minor shortcoming)

4. In-focus image (stripes are curved into a fan shape) Out-of-focus image warehouse (stripes are curved into a barrel shape) Negative correction (poor focus and poor resolution)

5. In-focus image (stripes are curved into a barrel 5 In-focus image (stripes are bent in a barrel shape) Out-of-focus image (stripes are bent in a fan shape) Overcorrected (poor focus and poor resolution)

6 In-focus image (stripes are undulated in thickness) Out-of-focus image (stripes are undulated in thickness) Not a serious defect but the curvature is uneven

7 In-focus image (stripes have large bends at the top and bottom) Out-of-focus image (large bends at the top and bottom of the stripe) Serious defect (large bends at the outer periphery. (It can be improved by narrowing the aperture of the mirror or lens.)

There are many other cases, but there are many examples on the Internet, so please search for them.

--------------------

Specifications Scale for 150 Lpi encoder Original plate quartz 0.4mm thick

Minimum slit tolerance ±0.003mm, minimum pitch tolerance ±0.002mm

-------------------